Hi, and welcome to our blog, we’re glad you’re here! If you caught our previous blog entry you’ll know that we have a brand new hardwood line in our showroom and one color, Thorndon hall, in-stock. This new hardwood line is finished with the premium Osmo Hardwax Oil Finish, and today we’re diving into what exactly it is, the benefits to it, and how to maintain it.

For all the details on our newest wood line check out our previous blog post here.

What is the Osmo Hardwax Oil Finish?

Osmo is one of, if not the most natural flooring finish available. It’s a combination of penetrating oils and hardwax. The oil is made of renewable plant raw materials like sunflower oil, soya oil, and thistle oil. The waxes are based on renewable plant raw materials like carnauba wax and paraffin.

How’s Osmo different than traditional flooring finishes?

Urethane

In the manufacturing process with a urethane floor, thin layers of polyurethane, typically with an aluminum oxide additive, are sprayed onto the floor in thin buildable layers for topical protection.

The Osmo Hardwax Oil finish is instead, rolled onto the surface using a roll coat machine, buffed, and left to soak into the grain, allowing it to protect the floor from the inside out. Typically 2-3 coats of finish are applied during manufacturing.

Oil finishes

Osmo is the original creator of this type of finish with over 50 years of experience in hardwax oil manufacturing. When it comes to an “oil finished hardwood”, there are currently no standards as to what can be considered an oiled finish. Other companies will use a small amount of oil (as little as 5%) and the remainder of the finish is a synthetic material much like a urethane and still classify it as an oil finish. With Osmo, oil is the primary ingredient.

Why choose a floor finished with Osmo Hardwax Oil Finish?

When properly maintained, an Osmo finished hardwood can last longer and be more forgiving to wear and tear over time when compared to a urethane finished hardwood floor. While all wood is prone to scratching, an Osmo finished hardwood is easier to repair - simply wipe some oil over the affected area and let it dry. Once the oil has absorbed back into the grain the scratch will blend right back in to the wood surface. Wood ages and develops a rich patina very gracefully, and by never needing to sand down the surface, you won’t ever remove the patina, rather re oil and allow the wood to continue to age beautifully.

Where is the Osmo Hardwax Oil made?

This product is made in Warendorf, Germany. The finish factory in Warendorf has been producing quality German products for 50+ years, and the Osmo Hardwax Oil is exported to over 60 countries around the world.

Who would be a good fit for an Osmo finished hardwood?

We would recommend Osmo finished floors to those who want to make an investment on a beautiful floor that will age gracefully and, when maintained properly, will be beautiful for generations to come.

We would also highly recommend an Osmo finished floor for heavy traffic commercial settings that want the beauty of a natural wood floor. In a commercial application, more frequent care and maintenance will be required.

What is the maintenance required of a floor with this finish?

For routine maintenance, floors should be swept/vacuumed and then mopped with the Osmo wash and care. Approximately once/year in addition to the routine maintenance Osmo Liquid Wax Refresher should be used.

All of the cleaning supplies necessary to maintaining the floor are available in-stock in our showroom. You can find the complete Osmo finish maintenance guidelines here.

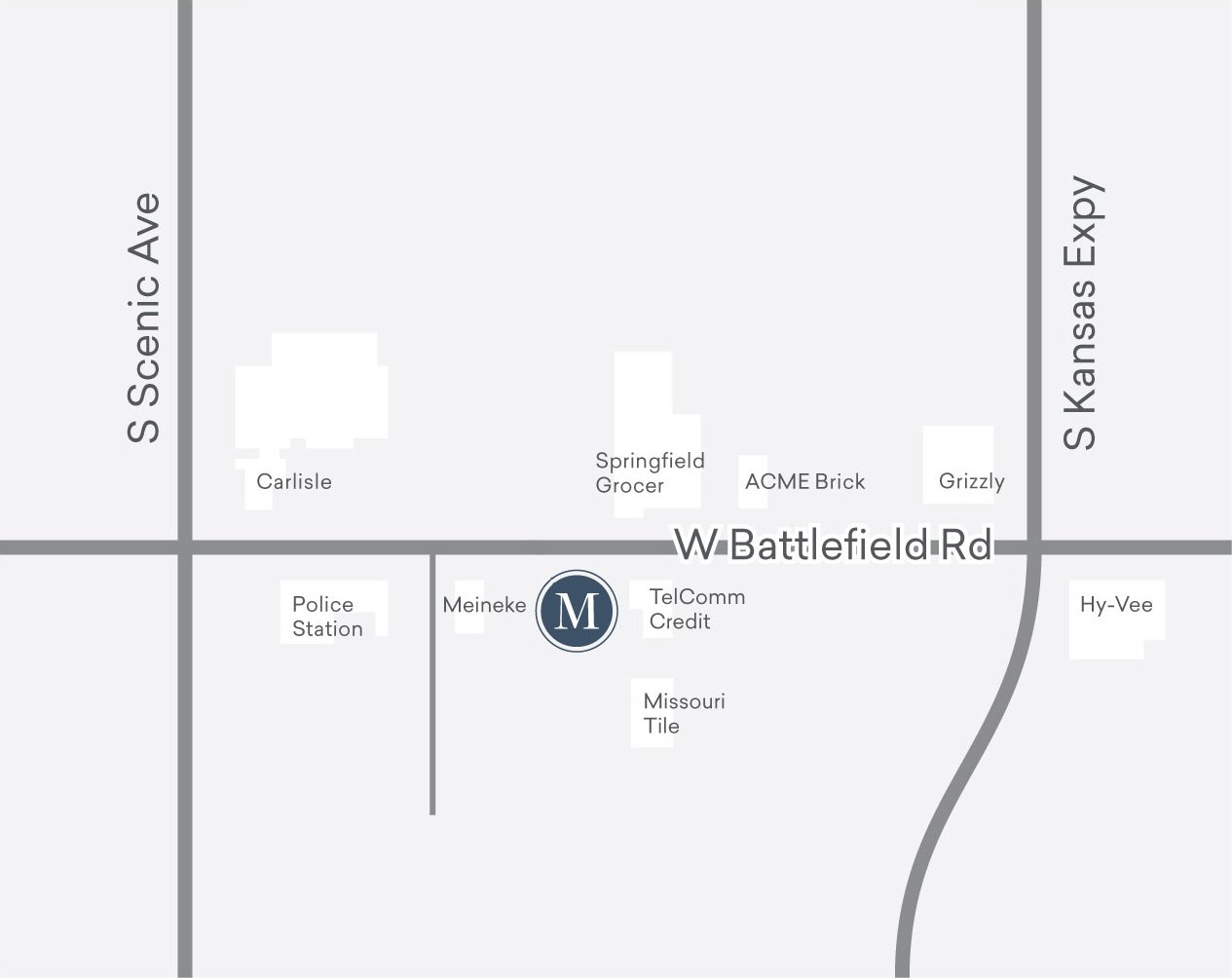

If you have any further questions about the Osmo Hardwax Oil finish we’d love to help. You can give us a call at (417) 883-4720, email us at flooring417@gmail.com, or visit our showroom located at 2516 W Battlefield Rd. in Springfield, Missouri.